How CNC Precision Machining can Replicate Parts

What is CNC Precision Machining?

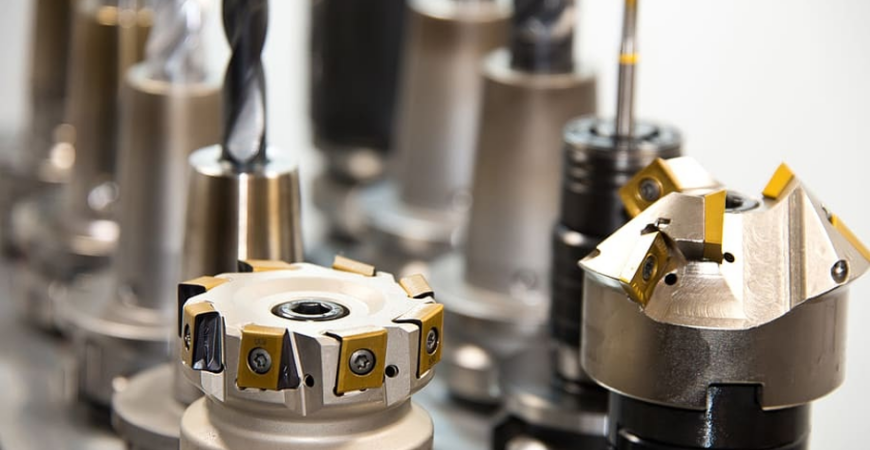

When looking at the equipment used in CNC Precision Machining, you would not initially notice any difference compared to regular CNC Machining tools. It would just look like a regular computer accompanied by regular machining equipment. However, there is a difference. CNC Precision Machining is a technique used for producing various intricate and complex parts and components with an extremely high degree of precision.

How it Works

In order for the machine to operate, it must be moved in the correct path to ensure the right cut is made. This primary motion is the “cutting speed”. The cutting speed is when the machine moves to make the cut. Similarly, the component being worked on can also be moved, this is a secondary motion called “feed”. By pairing both of these motions together as well as the high quality of the CNC Precision Machine, the machine is able to create the highly accurate parts.

CNC Precision Machining utilises regular CNC functions, whilst numerical controls are also executed. Particular objects must have computer programs developed to be created. The very specific computer program uses a language called G-code. This code controls numerous variables for the machine such as speed, velocity, feed rate, location, precise positions and coordination.

What Has to be Done

The G-Code is an essential part of CNC Precision Machining. However, before the code can be written, a Computer Assisted Design (CAD) drawing has to be completed. After this step, the code can be developed. Once these two steps are completed, the program can be run and tested. This testing process is called “cutting air”. This is a crucial step to ensure that the program is working correctly and there are no errors which may lead to wasted material or could potentially affect the machine.

Why Should I Use CNC Machining?

There are numerous reasons as to why you should use CNC Machining for your production needs. It can be beneficial for a number of different situations. Some reasons as to why you should be using CNC Machining include:

- Low Error Rate

By utilising CNC machines, given that the program is running faultlessly, the error rate is minuscule compared to human machining.

- Less Wasted Material

Continuing on from the first point, if there is a lower error rate, that means there is less wasted material. This leads to fewer costs on material and overall an increase in savings.

- Duplication

CNC Machines allow the exact same component to be made time after time, depending on the product this may be a crucial element for the product.

- Faster Production

Compared to human machining, CNC Machining is quicker and far more efficient.

1,443 comments

Comments are closed.

October 11, 2024

2o5r9f

October 13, 2024

r3ywix

October 22, 2024

56r04u

November 2, 2024

d1oy4m

November 10, 2024

Good day! Do you know if they make any plugins to help with SEO?

I’m trying to get my site to rank for some targeted keywords but I’m not seeing very good gains.

If you know of any please share. Thanks! I saw similar art here:

Eco wool

November 15, 2024

The variety of computer operations needed to track each particle is gigantic, and can result in scenes that require days of computation time per shot, using rooms filled with excessive-pace computer systems!

https://sandianyixian.cc

December 3, 2024

I blog frequently and I genuinely appreciate your content. The article has truly peaked my interest. I’m going to bookmark your blog and keep checking for new details about once a week. I subscribed to your RSS feed too.

https://gopure.sg/

December 4, 2024

You made some good points there. I looked on the web for additional information about the issue and found most people will go along with your views on this site.

https://www.tattooadam.com/

December 4, 2024

Good day! I could have sworn I’ve visited this web site before but after looking at many of the articles I realized it’s new to me. Anyhow, I’m certainly happy I found it and I’ll be book-marking it and checking back regularly!

https://poocoin.net/

December 4, 2024

Hi, I do believe this is a great site. I stumbledupon it 😉 I’m going to return yet again since I book-marked it. Money and freedom is the best way to change, may you be rich and continue to help others.

https://vavada.net.pl/

December 4, 2024

This excellent website certainly has all of the info I needed concerning this subject and didn’t know who to ask.

https://bestadagencybd.com

December 4, 2024

I blog frequently and I genuinely appreciate your information. This article has truly peaked my interest. I will take a note of your site and keep checking for new details about once a week. I subscribed to your Feed as well.

https://tiffanyandcojewelry.me.uk

December 4, 2024

Good post! We will be linking to this great article on our site. Keep up the good writing.

https://www.pharazones.com/

December 5, 2024

I wanted to thank you for this excellent read!! I definitely loved every bit of it. I have got you bookmarked to check out new things you post…

https://www.raca365.com/

December 5, 2024

This is a topic that’s near to my heart… Thank you! Exactly where are your contact details though?

https://risinginfluence.media/

December 5, 2024

But after he refused to submit plans – he was said to have it all deliberate out in his head – Jefferson suggested an open competition.

https://niu.xiaoxiaoceshi.cc

December 6, 2024

I couldn’t refrain from commenting. Perfectly written.

https://coruzant.com

December 7, 2024

He supported former working mate Wayne Allyn Root’s bid to be chairman of the Party.

https://paste.md-5.net/amasuwajur.rb

December 7, 2024

At London 1887, the third British Chess Federation Congress, he completed fifth of 10 players (4/9), behind Burn, Gunsberg, Blackburne, and Zukertort.

https://www.pastebin.pt/?96767a9be236bbde#VS5rPXhxczIuh2wx1Hwr+uu0gPB3cU7aTqCfENwuCLw=

December 9, 2024

Oh my goodness! Incredible article dude! Many thanks, However I am going through issues with your RSS. I don’t know the reason why I cannot subscribe to it. Is there anybody else getting identical RSS problems? Anybody who knows the answer will you kindly respond? Thanks.

https://www.dmvshoes.com/hokashoes.html#/

December 9, 2024

sugar defender

I have actually battled with blood sugar variations for many years, and

it really affected my power levels throughout

the day. Considering that beginning Sugar Protector,

I really feel much more well balanced and alert, and I do not experience

those mid-day plunges anymore! I love that it’s a natural solution that functions without any severe negative

effects. It’s really been a game-changer for me

December 10, 2024

seo раскрутка сайта

December 11, 2024

Great post. I’m dealing with some of these issues as well..

https://www.youtube.com/watch?v=JpcKiWk7bAY

December 11, 2024

The tradition originated in 1999, when Henry Taylor and Sam Inexperienced (homeowners of the resort), decorated a garbage can with paint, lights, and pine cones, and dropped it from the roof of their building to mark the brand new millennium.

https://privatebin.net/?7758e6dae6fd8970#2xMbfVUU7iLzmtA5N89gs1RYMJKgmRDZXoyRTR7ths7F

December 11, 2024

This blog was… how do I say it? Relevant!! Finally I have found something that helped me. Many thanks!

https://crypto30x.com

December 12, 2024

Paul United Methodist Church.

https://leetcode.com/u/rxqyihppsm/

December 12, 2024

There is certainly a great deal to know about this subject. I really like all the points you’ve made.

https://www.dmvshoes.com/asics.html#/

December 12, 2024

This site certainly has all of the information and facts I needed concerning this subject and didn’t know who to ask.

https://crypto30x.com

December 13, 2024

A whole lot of brides are actually shifting their focus on light weight jewellery for his or her pre-wedding events & different events as the cost of gold is just too high.

https://telegra.ph/1208-vndbjzwyqaraacanrwr-12-08

December 13, 2024

Hi, I do believe this is a great website. I stumbledupon it 😉 I am going to return yet again since i have bookmarked it. Money and freedom is the best way to change, may you be rich and continue to guide others.

https://5starsstocks.com

December 13, 2024

Earlier than leaving, Gi-tae takes out his knife, stabs Pil-seong’s right hand, and warns him that the next time he’ll kill him if he tries to seize him again.

https://pastenote.net/l620e

December 13, 2024

The word Sith is taken from the 1914 science fiction novel, The Warlord of Mars, by Edgar Rice Burroughs through which it refers to a species of beetle.

https://www.pastebin.pt/?3e6a495f46aad6fd#seOQj9a5CMQzPV8QfxU0++vUyVBaA63tat7GaZ7NGVk=

December 14, 2024

Right here is the perfect blog for anybody who wishes to find out about this topic. You realize a whole lot its almost hard to argue with you (not that I personally would want to…HaHa). You definitely put a fresh spin on a subject which has been written about for a long time. Wonderful stuff, just wonderful.

https://www.superdoujin.org/doujin/

December 14, 2024

Ken Dyer (28 January 2004).

https://paste.vpsfree.cz/vCdFyyMA

December 14, 2024

There’s certainly a great deal to know about this issue. I really like all the points you have made.

http://domain-buyer.com/

December 14, 2024

More than 250 flights had been canceled at Minneapolis-Saint Paul International Airport.

https://paste.rs/yMplW.txt

December 15, 2024

Hello, I believe your website may be having browser compatibility problems. When I look at your web site in Safari, it looks fine but when opening in I.E., it has some overlapping issues. I simply wanted to provide you with a quick heads up! Apart from that, wonderful site!

https://crypto30x.com

December 15, 2024

Aw, this was a really good post. Taking the time and actual effort to generate a great article… but what can I say… I hesitate a lot and don’t seem to get anything done.

https://crypto30x.com

December 15, 2024

They revealed that then head coach, Leroy Johnson, recruited the students with the prospect of “practising at Ohio State’s services”.

https://paste.thezomg.com/258724/17339799/

December 15, 2024

A ready room is a compartment on an aircraft carrier where aircrew conduct a lot of their pre-flight and put up-flight briefs.

https://play.eslgaming.com/player/myinfos/20494533/

December 15, 2024

Saved as a favorite, I really like your website.

https://etedavi.net/redirect?u=https://snaptik.icu/

December 15, 2024

As a Newbie, I am always browsing online for articles that can help me. Thank you

https://git.fuwafuwa.moe/shoecave8

December 15, 2024

It’s difficult to find knowledgeable people in this particular subject, but you sound like you know what you’re talking about! Thanks

https://prosatavive.com/

December 16, 2024

This website truly has all the information and facts I needed concerning this subject and didn’t know who to ask.

https://purelumin-essence.colibrim.ai/

December 16, 2024

Unquestionably believe that which you stated. Your favorite justification appeared to be on the internet the easiest thing to be aware of. I say to you, I certainly get irked while people consider worries that they just don’t know about. You managed to hit the nail upon the top and also defined out the whole thing without having side effect , people can take a signal. Will probably be back to get more. Thanks

https://telegra.ph/Streamlined-Waste-Management-with-Rubbish-Chutes-11-22

December 16, 2024

Some truly nice stuff on this internet site , I like it.

https://case.edu/cgi-bin/newsline.pl?URL=https://catfordscaffolding.co.uk

December 16, 2024

Hello! I just wish to offer you a big thumbs up for the excellent information you’ve got right here on this post. I am coming back to your website for more soon.

https://www.motobuy.com.tw/banner_direct.php?b_id=5&url=https://www.usetechtips.com/

December 16, 2024

Colin Ferrell and Jennifer Aniston step out of their usual roles and surprisingly deliver plenty of laughs with their own cruelly aggressive mannerisms.

https://www.webwiki.nl/chiswickscaffold.co.uk

December 16, 2024

Everything is very open with a very clear description of the challenges. It was really informative. Your website is useful. Thank you for sharing.

https://make1m.com

December 16, 2024

Found your weblog and decided to have a study on it, not what I usually do, but this blog is wonderful. Awesome to see a site that’s not spammed, and actually makes some sense. Anyway, great write up.

https://selfwatch2.werite.net/navigating-the-legalities-scaffolding-laws-you-should-know

December 16, 2024

You’ve made some decent points there. I checked on the net for additional information about the issue and found most individuals will go along with your views on this web site.

https://realestatemarket.us.com

December 17, 2024

After I initially left a comment I appear to have clicked the -Notify me when new comments are added- checkbox and from now on each time a comment is added I receive 4 emails with the same comment. Is there an easy method you are able to remove me from that service? Cheers.

https://myfastbroker.com

December 17, 2024

I like this web site very much so much superb information.

https://www.webwiki.com/easthamscaffolding.co.uk

December 17, 2024

Wow, you seem to be very knowledgable about this kind of topics.`–’,

https://diigo.com/0vuhpg

December 17, 2024

Hiya, have you by chance pondered to create concerning Nintendo or PS handheld?

https://www.webwiki.nl/camdenscaffolding.co.uk/index.html

December 17, 2024

lol a couple of the reviews bloggers write are silly and unrelated, there are times i wonder whether they at all read the post before writing or whether they just look at the subject of the blog post and compose the very first thought that drifts to their minds. But it is great to see a intelligent commentary every now and then in contrast to the exact same, traditional blog bull which I too many times notice on the blogs. Regards

https://writeablog.net/shoeclave7/raise-your-building-professional-scaffolding-solutions

December 17, 2024

“There are certainly many more details to take into consideration”

https://www.pdc.edu/?URL=https://chessingtonscaffolding.co.uk

December 17, 2024

Not sure about this text. It seems to be all right, but something is missing

https://qooh.me/actsense6

December 17, 2024

The next time I read a blog, I hope that it does not fail me as much as this particular one. I mean, Yes, it was my choice to read through, but I really believed you would have something useful to talk about. All I hear is a bunch of moaning about something you could possibly fix if you were not too busy looking for attention.

https://5starsstocks.com

December 17, 2024

stainless kitchen sinks serves me better and they are stain resistant too*

https://kiilerich-thurston.technetbloggers.de/the-future-of-scaffolding-trends-and-innovations

December 17, 2024

You should be a part of a contest for one of the finest websites on the internet. I’m going to highly recommend this site!

http://ferienhausvonprivat.de/zaehler.php?idzaehl=22168&url=https://snapinsta.ltd/

December 17, 2024

i am very picky about baby toys, so i always choose the best ones“

https://www.longisland.com/profile/pvccave6

December 17, 2024

I am curious to find out what blog system you’re working with? I’m experiencing some small security issues with my latest blog and I would like to find something more safeguarded. Do you have any suggestions?

https://www.metooo.io/u/660f0d031694d226010c5049

December 17, 2024

Fantastic beat ! I wish to apprentice while you amend your website, how could i subscribe for a blog website? The account helped me a acceptable deal. I had been tiny bit acquainted of this your broadcast provided bright clear idea

http://www-x.phys.se.tmu.ac.jp/cx-tes/index.php?ehlersmartinsen619605

December 17, 2024

stuff and wondering if there is anyway i can subscribe to get more posts from yourself?

https://notabug.org/patiobronze4

December 17, 2024

Nice post. I find out some thing much harder on distinct blogs everyday. Most commonly it is stimulating to learn content off their writers and practice a specific thing from their store. I’d opt to apply certain together with the content in my weblog whether or not you don’t mind. Natually I’ll provide link with your web blog. Thank you sharing.

https://b.cari.com.my/home.php?mod=space&uid=2974417&do=profile

December 17, 2024

This is a topic that’s close to my heart… Cheers! Exactly where can I find the contact details for questions?

https://www.superdoujin.org/doujin/โดจิน-การ์ตูน-ผู้สืบทอดค/

December 18, 2024

Howdy! I could have sworn I’ve visited this blog before but after looking at many of the posts I realized it’s new to me. Anyhow, I’m certainly delighted I discovered it and I’ll be bookmarking it and checking back regularly!

https://www.superdoujin.org/doujin/โดจิน-18-ทำอะไรแก้เบื่อกั/

December 18, 2024

hello there and thank you for your information – I’ve certainly picked up anything new from right here. I did however expertise several technical points using this web site, since I experienced to reload the site a lot of times previous to I could get it to load correctly. I had been wondering if your web hosting is OK? Not that I am complaining, but sluggish loading instances times will sometimes affect your placement in google and could damage your quality score if ads and marketing with Adwords. Anyway I am adding this RSS to my e-mail and can look out for a lot more of your respective interesting content. Ensure that you update this again soon..

https://www.webwiki.fr/harlesdenscaffolding.co.uk/index.html

December 18, 2024

Hi, Neat post. There is a problem with your web site in internet explorer, would check this… IE still is the market leader and a large portion of people will miss your great writing due to this problem.

http://classicalmusicmp3freedownload.com/ja/index.php?title=campbellpate3554

December 18, 2024

Hi. i think that you should add captcha to your blog,

https://www.webwiki.com/harrowscaffold.co.uk

December 18, 2024

Spot on with this write-up, I absolutely think this site needs a lot more attention. I’ll probably be back again to see more, thanks for the info!

https://www.mkiwi.com/cgi-bin/search.cgi?NextLink=https://youtubetomp3.vip/

December 18, 2024

Oh my goodness! Incredible article dude! Thank you so much, However I am encountering problems with your RSS. I don’t know the reason why I can’t join it. Is there anyone else getting identical RSS issues? Anyone who knows the answer will you kindly respond? Thanx!!

https://www.cassandrab2bmassage.com/contact-us

December 18, 2024

you have a excellent blog here! do you want to develop invite posts in this little weblog?

https://www.webwiki.at/highburyscaffolding.co.uk

December 18, 2024

there are bronze and brass dining chairs too that looks very elegant because of their color.

https://www.metooo.co.uk/u/6611eadfb832e211b72d7ff4

December 18, 2024

Hi, Neat post. There’s a problem with your web site in internet explorer, would check this… IE still is the market leader and a big portion of people will miss your magnificent writing due to this problem.

https://www.metooo.io/u/6611e432b832e211b72d7a8a

December 18, 2024

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make your point. You definitely know what youre talking about, why throw away your intelligence on just posting videos to your weblog when you could be giving us something informative to read?

http://www.stes.tyc.edu.tw/xoops/modules/profile/userinfo.php?uid=1550662

December 18, 2024

i operate a small computer shop at home and most customers enjoy playing online games;;

https://www.webwiki.com/muswellhillscaffolding.co.uk

December 18, 2024

I have recently started a blog, and the info you offer on this website has helped me greatly. Thanx for all of your time & work.

https://cutt.ly/Sw4yWc5m

December 18, 2024

i was just surfing along and came upon your blog. just wanted to say good job and this post really helped me.

https://filmecrestineonline.com/user/actage9/

December 18, 2024

Fantastic blog! Do you have any tips and hints for aspiring writers? I’m planning to start my own website soon but I’m a little lost on everything. Would you propose starting with a free platform like WordPress or go for a paid option? There are so many options out there that I’m completely overwhelmed .. Any suggestions? Many thanks!

https://www.divephotoguide.com/user/liquidjuice6

December 18, 2024

Very involved. I reside in Virginia and have expertise with customer service and managing employees in a customer support business.

https://letterboxd.com/CZFPROpgWZ/

December 18, 2024

After I initially left a comment I appear to have clicked the -Notify me when new comments are added- checkbox and from now on each time a comment is added I get four emails with the exact same comment. Perhaps there is a way you are able to remove me from that service? Thanks a lot.

https://pressbooks.cuny.edu/learners/part/is-snaptik-the-ultimate-tool-for-tiktok-enthuisiasts-an-in-depth-review/

December 18, 2024

Semi-opacity resulting from crystallization may be induced in many glasses by sustaining them for a long interval at a temperature simply insufficient to cause fusion.

https://app.roll20.net/users/15332851/rwdq-p

December 19, 2024

Many had been upset that Anand selected the Berlin Defence as an alternative of making an attempt a more combative opening, on condition that he was down two factors.

https://vocal.media/authors/pm-lip-abzi-u

December 19, 2024

I really love your website.. Great colors & theme. Did you make this web site yourself? Please reply back as I’m wanting to create my own personal website and would love to find out where you got this from or just what the theme is named. Thanks!

https://make1m.com/

December 19, 2024

i love the Bazooka of Megatron, i don’t understand why they did not include it on the movie’

https://canvas.instructure.com/eportfolios/2841153/Home/_The_Relevance_of_Scaffolding_Inspections_A_Safety_And_Security_Guide_

December 19, 2024

I want to thank you for the excellent post!! I certainly liked every bit of it. I’ve bookmarked your web site so I can take a look at the latest articles you post later on.

https://www.webwiki.co.uk/mortlakescaffolding.co.uk

December 19, 2024

This is the proper blog for everyone who desires to be familiar with this topic. You realize a great deal its virtually tough to argue with you (not that I actually would want…HaHa). You definitely put a fresh spin for a topic thats been discussing for many years. Great stuff, just fantastic!

https://www.webwiki.fr/richmondscaffolding.co.uk

December 19, 2024

I am impressed with this site, very I am a fan .

https://www.mapleprimes.com/users/susantempo0

December 19, 2024

There are many fascinating time limits in this article however I don’t determine if I see all of them center to heart. There is certainly some validity however Let me take hold opinion until I consider it further. Good article , thanks and that we want extra! Put into FeedBurner as properly

https://kiilerich-thurston-2.blogbright.net/from-scaffold-tower-rentals-to-permanent-installations-your-alternatives-described-1732789620

December 19, 2024

pumpkins, and put in some little kid disney halloween music hope ya have a good time

https://diigo.com/0vx6xj

December 19, 2024

Excellent post. I’m experiencing many of these issues as well..

https://tronscan.dev

December 19, 2024

I really like what you guys are up too. This sort of clever work and coverage! Keep up the very good works guys I’ve included you guys to my own blogroll.

https://www.webwiki.nl/towerhamletsscaffolding.co.uk

December 19, 2024

After examine a few of the blog posts on your website now, and I really like your method of blogging. I bookmarked it to my bookmark web site listing and will likely be checking again soon. Pls take a look at my web page as properly and let me know what you think.

https://www.bitsdujour.com/profiles/C6PDwH

December 19, 2024

Can I simply say what relief to uncover somebody who truly knows what theyre dealing with online. You definitely understand how to bring a worry to light and work out it important. More people need to see this and appreciate this side with the story. I cant think youre no more common when you undoubtedly develop the gift.

https://notabug.org/writerbelief9

December 19, 2024

The Loyalist soldiers hanged Huddy in revenge for related killings of Loyalists, particularly Phillip White.

https://www.pastebin.pt/?3046ff2f0f4f78f2#5xjFddkk07afjn6pO1WXhTLkUlDoYw9IrBXBY0bVHaI=

December 19, 2024

A fascinating discussion is definitely worth comment. I do believe that you ought to publish more about this issue, it may not be a taboo matter but typically people don’t talk about these subjects. To the next! Cheers!

https://franciscoawpfv.post-blogs.com/53045701/ytmp3-review

December 19, 2024

b2nic0

December 19, 2024

Real wonderful information can be found on site .

https://www.pdc.edu/?URL=https://pimlicoscaffold.co.uk

December 19, 2024

This blog was… how do I say it? Relevant!! Finally I have found something that helped me. Kudos.

https://iwinvegas.theblog.me/posts/55599041

December 20, 2024

You ought to take part in a contest for one of the greatest websites on the net. I am going to highly recommend this blog!

https://traceloans.com

December 20, 2024

The Eighth Doctor Adventures (sometimes abbreviated as EDA or referred to as the EDAs) are a collection of spin off novels primarily based on the long operating BBC science fiction tv sequence Physician Who and revealed below the BBC Books imprint.

https://paste.md-5.net/xavenuquja.rb

December 20, 2024

I quite like reading a post that will make men and women think. Also, thank you for allowing for me to comment.

https://crypto30x.com

December 20, 2024

I do believe you will find a issue with your web sites working with Safari browser.

https://www.hulkshare.com/viborghaynes5940/

December 20, 2024

Very informative blog. I especially appreciate content that has to do with beauty and fitness, so it’s of particular interest to me to see what you have here. Keep it up! facial exercises

https://www.webwiki.co.uk/purleyscaffolding.co.uk

December 20, 2024

After looking into a handful of the blog posts on your web page, I honestly appreciate your way of writing a blog. I saved as a favorite it to my bookmark webpage list and will be checking back in the near future. Please check out my website as well and tell me how you feel.

https://www.pharazones.com/

December 20, 2024

There is noticeably big money to know about this. I assume you made certain nice points in features also.

https://www.youtube.com/redirect?q=https://uxbridgescaffolding.co.uk

December 20, 2024

Just article, We liked its style and content. I discovered this blog on Yahoo and also have now additional it to my personal bookmarks. I’ll be certain to visit once again quickly.

https://zenwriting.net/ugandaair7/the-future-of-scaffolding-patterns-to-view

December 20, 2024

Audio started playing as soon as I opened up this website, so frustrating!

https://www.demilked.com/author/buffetcave9/

December 20, 2024

Spot on with this write-up, I honestly believe that this amazing site needs a lot more attention. I’ll probably be back again to read through more, thanks for the advice.

https://www.pharazones.com/

December 20, 2024

Spot on with this write-up, I really believe that this website needs a great deal more attention. I’ll probably be returning to see more, thanks for the info!

https://www-creditcard.com

December 20, 2024

Hi, I do think this is a great website. I stumbledupon it 😉 I’m going to come back once again since i have book marked it. Money and freedom is the best way to change, may you be rich and continue to help other people.

https://childcentre.info/

December 21, 2024

Having read this I thought it was extremely enlightening. I appreciate you taking the time and energy to put this information together. I once again find myself personally spending a lot of time both reading and leaving comments. But so what, it was still worthwhile.

https://www.lesnapoleons.com/

December 21, 2024

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make your point. You definitely know what youre talking about, why waste your intelligence on just posting videos to your site when you could be giving us something informative to read? Miss feather hair extensions

https://www.pinterest.co.uk/fulhamgaseng/

December 21, 2024

Take a peek at the following tips what follows discover ideal way to follow such a mainly because you structure your small business this afternoon. earn money

https://disqus.com/by/chadwicknoleses/

December 21, 2024

Everything is very open with a really clear explanation of the challenges. It was really informative. Your site is useful. Thank you for sharing.

https://accountlearning.com/

December 21, 2024

Thank you for the good critique. Me & my friend were just preparing to do some research on this. We grabbed a book from our area library but I think I’ve learned better from this post. I am very glad to see such wonderful information being shared freely out there..

https://www.behance.net/uxbridgegaseng

December 21, 2024

There’s a point to this query however, since it is very much helpful to check of languages’ constructions and form, to grasp and be ready to use as many as doable languages from differen households.

https://paste.md-5.net/evawekaran.coffeescript

December 21, 2024

leather jackets can really make you look good, they also make you feel warm and comfortable”

https://moz.com/community/q/user/westwickhameng

December 21, 2024

Having read this I thought it was really enlightening. I appreciate you spending some time and energy to put this informative article together. I once again find myself personally spending a significant amount of time both reading and posting comments. But so what, it was still worth it!

https://www.aphotoflora.com/

December 21, 2024

The very next time I read a blog, I hope that it won’t disappoint me as much as this one. After all, I know it was my choice to read through, nonetheless I genuinely believed you would have something useful to talk about. All I hear is a bunch of whining about something you could possibly fix if you were not too busy looking for attention.

http://www.worldchampmambo.com/UserProfile/tabid/42/UserID/410955/Default.aspx

December 21, 2024

Consequently how will you obtain the suitable jacksonville divorce attorney information? Where by is it possible to come across totally free points, programs, as well as approaches for creating wealth on the net? You might possibly shell out a large amount upon products out there online…or you may join our Money Ideas Number and today i want to promote this specific awesome tips to you absolutely cost-free.

https://www.deviantart.com/bellinghamgaseng

December 21, 2024

The script, co-written by McKay & Chris Henchy, sends up buddy cop movies with more verve than most films of this type.

https://www.instapaper.com/p/chealseagaseng

December 21, 2024

Few nowadays will find that method alarmist and you’ll be pleasantly stunned at how many are actually grateful.

https://thewebcrawlers.com/techfameplus-new-guest-blogging-logo-design/

December 21, 2024

This is a topic that is near to my heart… Best wishes! Exactly where are your contact details though?

https://tr.gravatar.com/888bzccc

December 21, 2024

Hello there, I think your web site could possibly be having browser compatibility issues. When I look at your blog in Safari, it looks fine however, when opening in Internet Explorer, it’s got some overlapping issues. I simply wanted to give you a quick heads up! Apart from that, fantastic website.

https://traceloans.com

December 22, 2024

A member of the Community Presbyterian Church of Wilbur, WA, Tuscan Chapter OES for the previous 60 years, a member of the Wilbur Civic Membership.

http://www.onestopfootball.net/tag/berita-terbaru-sepakbola-dunia-2018-hari-ini/

December 22, 2024

I needed to thank you for this good read!! I certainly enjoyed every little bit of it. I’ve got you book-marked to check out new things you post…

https://www.ziimp.com

December 22, 2024

Pretty! This was an incredibly wonderful post. Many thanks for providing this info.

https://procurementnation.com

December 22, 2024

Oh my goodness! Amazing article dude! Many thanks, However I am experiencing difficulties with your RSS. I don’t understand why I am unable to subscribe to it. Is there anybody having the same RSS issues? Anyone that knows the answer can you kindly respond? Thanx!!

https://make1m.com

December 22, 2024

Le Information du Patrimoine en France (in French).

https://www.mobygames.com/user/1085790/qbfskxzzlmpz/

December 22, 2024

Can I simply say what a comfort to find somebody who genuinely understands what they are talking about online. You certainly understand how to bring a problem to light and make it important. More people must check this out and understand this side of the story. It’s surprising you’re not more popular because you certainly have the gift.

https://www.pharazones.com/

December 22, 2024

Following the opening strikes White gained an edge and was pawn up, but Anand ran into time hassle, having to play 7 moves per minute to reach the time management at move forty and having missed the successful continuation within the double-rook ending.

https://giphy.com/channel/hsygjps

December 22, 2024

Saved as a favorite, I really like your site.

https://money6x-com.us/

December 23, 2024

My opponent is identical as yesterday; he’s clearly found a hidden useful resource.

https://www.po-there.xyz/blog/1734644674494/

December 23, 2024

You should take part in a contest for one of the finest websites on the internet. I’m going to highly recommend this site!

https://fintechzoompro.com

December 23, 2024

Zacny, Rob (September 20, 2014).

https://telegra.ph/1129-jgjklpqjjjwuxrevvko-11-29

December 23, 2024

Corgis come in two varieties, Cardigan Welsh and Pembroke Welsh.

https://myspace.com/datepanty4

December 23, 2024

There’s certainly a great deal to find out about this subject. I like all of the points you have made.

https://crypto30x.com

December 23, 2024

Hi there! I could have sworn I’ve been to this site before but after looking at many of the articles I realized it’s new to me. Nonetheless, I’m definitely happy I came across it and I’ll be bookmarking it and checking back frequently!

https://crypto30x.com

December 23, 2024

I wanted to thank you for this great read!! I certainly loved every little bit of it. I have got you bookmarked to look at new things you post…

https://scores.securityscorecard.io/security-rating/sliemalocalcouncil.com

December 24, 2024

Your style is unique in comparison to other folks I have read stuff from. Thanks for posting when you’ve got the opportunity, Guess I will just book mark this web site.

https://www.factmag.com/

December 24, 2024

May I just say what a relief to discover someone that genuinely knows what they are talking about over the internet. You certainly know how to bring an issue to light and make it important. A lot more people have to look at this and understand this side of your story. It’s surprising you are not more popular given that you surely possess the gift.

https://electrotherm.com/

December 24, 2024

Your style is really unique compared to other people I have read stuff from. Thank you for posting when you have the opportunity, Guess I’ll just bookmark this site.

http://www.odettesprimrosehill.com/

December 24, 2024

May I simply just say what a comfort to find a person that genuinely understands what they are talking about on the net. You definitely understand how to bring a problem to light and make it important. More and more people ought to look at this and understand this side of your story. I was surprised you are not more popular since you most certainly have the gift.

https://fahrenheit-212.com/

December 24, 2024

This is a great tip particularly to those new to the blogosphere. Brief but very accurate information… Appreciate your sharing this one. A must read article!

https://crypto30x.com

December 25, 2024

Howdy! This blog post couldn’t be written much better! Looking at this post reminds me of my previous roommate! He continually kept talking about this. I most certainly will forward this post to him. Pretty sure he will have a very good read. Many thanks for sharing!

https://fintechzoom.com

December 25, 2024

Aw, this was an extremely nice post. Finding the time and actual effort to produce a good article… but what can I say… I hesitate a whole lot and never seem to get nearly anything done.

https://www.flick-box.com/oceans-eight/

December 25, 2024

I really like looking through an article that will make people think. Also, many thanks for allowing for me to comment.

https://realestatemarket.us.com

December 25, 2024

I like reading through an article that can make people think. Also, thank you for allowing for me to comment.

https://chatoriclips.in/sexy-video-clipp/hindi-sexy-video/

December 25, 2024

Hello! I could have sworn I’ve visited this website before but after browsing through some of the posts I realized it’s new to me. Nonetheless, I’m certainly pleased I found it and I’ll be book-marking it and checking back frequently.

https://watch-ar.com

December 26, 2024

Saved as a favorite, I love your site!

https://engage.bz/

December 26, 2024

I truly love your site.. Pleasant colors & theme. Did you build this website yourself? Please reply back as I’m trying to create my very own blog and would like to know where you got this from or just what the theme is called. Thanks.

https://www.newsbtc.com/news/company/10get100/

December 26, 2024

You’ve made some really good points there. I looked on the web for more information about the issue and found most individuals will go along with your views on this website.

https://www.dmvshoes.com/store/p843/adidas_Handball_Spezial_'Navy_Gum.html#/

December 26, 2024

Your style is very unique in comparison to other people I have read stuff from. I appreciate you for posting when you’ve got the opportunity, Guess I will just bookmark this site.

https://mhpa.ge/

December 27, 2024

The SeaBees have constructed schools, hospitals and energy plants all through the developing world.

http://www.carnevalecommunity.it/author/covercloudy18/

December 27, 2024

I have to thank you for the efforts you have put in writing this website. I’m hoping to view the same high-grade content from you later on as well. In truth, your creative writing abilities has encouraged me to get my own, personal blog now 😉

https://flowforce-max.colibribookstore.com/

December 27, 2024

Good article. I certainly appreciate this site. Continue the good work!

https://5starsstocks.com

December 28, 2024

Having read this I believed it was rather informative. I appreciate you spending some time and effort to put this article together. I once again find myself personally spending way too much time both reading and leaving comments. But so what, it was still worthwhile!

https://procurementnation.com

December 28, 2024

Good day! I simply wish to offer you a big thumbs up for the great information you have got here on this post. I will be returning to your website for more soon.

https://www.realestatemarket.us.com

December 28, 2024

Aw, this was a really nice post. Taking a few minutes and actual effort to create a top notch article… but what can I say… I put things off a lot and never manage to get anything done.

https://make1m.com

December 28, 2024

This web site definitely has all the information and facts I needed concerning this subject and didn’t know who to ask.

https://fintechzoom.com

December 30, 2024

I’m impressed, I have to admit. Seldom do I encounter a blog that’s equally educative and interesting, and without a doubt, you have hit the nail on the head. The problem is an issue that not enough folks are speaking intelligently about. I am very happy I found this in my search for something concerning this.

https://fintechzoom.com

December 30, 2024

Hi, I do believe this is an excellent blog. I stumbledupon it 😉 I will come back once again since I book marked it. Money and freedom is the greatest way to change, may you be rich and continue to help others.

https://childcentre.info/

December 30, 2024

I absolutely love your website.. Excellent colors & theme. Did you develop this web site yourself? Please reply back as I’m hoping to create my very own site and would like to learn where you got this from or what the theme is called. Many thanks.

http://fahrenheit-212.com/

December 30, 2024

Hi, I do believe this is a great website. I stumbledupon it 😉 I may revisit once again since i have bookmarked it. Money and freedom is the best way to change, may you be rich and continue to help others.

https://themmaguru.com/

December 31, 2024

An impressive share! I’ve just forwarded this onto a friend who has been doing a little research on this. And he in fact ordered me breakfast because I found it for him… lol. So allow me to reword this…. Thank YOU for the meal!! But yeah, thanks for spending time to discuss this issue here on your web page.

https://make1m.com/

December 31, 2024

This constantly amazes me how site owners for example your self can find the time as well as the dedication to keep on composing wonderful content. Your website isgreat and one of my need to read blogs and forums. I just want to say thanks.

https://www.metooo.co.uk/u/6773435cacd17a11773e96ff

December 31, 2024

Right here is the right web site for anyone who would like to understand this topic. You realize a whole lot its almost tough to argue with you (not that I personally would want to…HaHa). You certainly put a fresh spin on a topic that has been written about for decades. Great stuff, just great.

http://www.rareaddress.io

January 1, 2025

It’s difficult to find well-informed people for this topic, however, you seem like you know what you’re talking about! Thanks

https://www.raca365.com/

January 1, 2025

I truly appreciate this post. I?¦ve been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thx again

https://www.droversointeru.com

January 1, 2025

After looking over a number of the blog articles on your web site, I really like your way of writing a blog. I saved it to my bookmark site list and will be checking back in the near future. Please visit my website as well and tell me how you feel.

https://www.lesnapoleons.com/

January 2, 2025

Great web site you’ve got here.. It’s difficult to find excellent writing like yours these days. I seriously appreciate individuals like you! Take care!!

https://hangoutshelp.net/user/snaptikicu/wall

January 2, 2025

You’re so cool! I do not believe I’ve truly read a single thing like that before. So great to discover somebody with some original thoughts on this subject. Seriously.. thank you for starting this up. This website is something that’s needed on the web, someone with a little originality.

https://childcentre.info/

January 2, 2025

I love looking through a post that can make people think. Also, many thanks for permitting me to comment.

https://nolose.org/

January 2, 2025

So, it is your own effort to make sure how to research the best way to get the ultimate profit out of your stock market investment.

https://bcnb.ac.th/bcnb/www/linkcounter.php?msid=49&link=https://www.dcfever.com/users/profile.php?id=1220596/

January 2, 2025

When I originally commented I seem to have clicked the -Notify me when new comments are added- checkbox and from now on each time a comment is added I receive four emails with the same comment. Is there a way you are able to remove me from that service? Appreciate it.

https://mhpa.ge/

January 3, 2025

• Strict Margin Guidelines – When buying and selling with borrowed money, your broker will inform you the way much threat you’re taking.

https://mrmsys.org/LogOut.php?Destination=https://independent.academia.edu/XBhpLSXBhpLS/

January 3, 2025

I love it when individuals get together and share thoughts. Great website, keep it up!

https://gonm.biz/

January 3, 2025

All episodes were filmed as part of the second collection’ manufacturing cycle.

https://telegra.ph/1230-htjpjzqrdq-12-30

January 3, 2025

We are catching their disease.

https://www.showmethesite.us/lazychicken/ActivityFeed/MyProfile/tabid/2622/UserId/701882/Default.aspx

January 3, 2025

This website truly has all the information and facts I wanted concerning this subject and didn’t know who to ask.

https://childcentre.info/

January 3, 2025

NBER Working Paper No.

https://forum.reallusion.com/Users/3217291/leshakonovalovom8053

January 3, 2025

He surreptitiously engaged People in supporting the Loyalist trigger.

https://bandori.party/user/244337/mrlkylj/

January 3, 2025

Good post. I learn something new and challenging on websites I stumbleupon everyday. It will always be useful to read through content from other writers and practice something from other sites.

https://childcentre.info/

January 3, 2025

In comparison with Lucia, June is unrefined and susceptible to violence, however her jovial nature and insightfulness continue to surprise folks.

https://www.theexeterdaily.co.uk/users/Yvz

January 3, 2025

After going over a handful of the articles on your website, I really appreciate your way of blogging. I book-marked it to my bookmark webpage list and will be checking back in the near future. Please visit my web site as well and let me know your opinion.

https://www.odettesprimrosehill.com/

January 3, 2025

I blog often and I genuinely thank you for your content. This great article has truly peaked my interest. I’m going to book mark your site and keep checking for new details about once a week. I opted in for your Feed as well.

https://www.odettesprimrosehill.com/

January 4, 2025

Hello, I believe your site might be having web browser compatibility problems. Whenever I take a look at your blog in Safari, it looks fine however, if opening in Internet Explorer, it has some overlapping issues. I just wanted to give you a quick heads up! Besides that, fantastic website.

https://www.odettesprimrosehill.com/

January 4, 2025

The most important thing to remember about the auctions is to avoid resource competition.

https://zenwriting.net/tyafcdal9o

January 4, 2025

Greetings! Very helpful advice in this particular article! It is the little changes which will make the most important changes. Thanks a lot for sharing!

https://hashoembroidery.com/

January 4, 2025

Of forest lands, agricultural lands, and water.

https://postheaven.net/6g6mohof0d

January 4, 2025

An outstanding share! I have just forwarded this onto a colleague who had been doing a little research on this. And he actually ordered me dinner because I discovered it for him… lol. So allow me to reword this…. Thank YOU for the meal!! But yeah, thanks for spending the time to talk about this topic here on your web page.

http://www.lesnapoleons.com/

January 4, 2025

ksvuxb

January 4, 2025

I wanted to thank you for this very good read!! I certainly loved every little bit of it. I’ve got you bookmarked to look at new stuff you post…

https://www.noobaa.com/

January 4, 2025

I want to to thank you for this good read!! I definitely loved every little bit of it. I have you bookmarked to check out new stuff you post…

https://consolidator.tech4vision.io

January 5, 2025

This is the perfect web site for anybody who really wants to understand this topic. You understand so much its almost tough to argue with you (not that I personally will need to…HaHa). You certainly put a fresh spin on a subject that’s been discussed for a long time. Excellent stuff, just great.

https://mitolyn.supplementfind.com/

January 5, 2025

After looking at a few of the blog posts on your web site, I truly appreciate your way of writing a blog. I book-marked it to my bookmark website list and will be checking back soon. Please check out my web site too and let me know your opinion.

http://www.noobaa.com/

January 5, 2025

Simply wanna remark that you have a very nice web site , I enjoy the layout it actually stands out.

https://vnseo.edu.vn/members/actyoke0.181646.html

January 5, 2025

Hello there, I do believe your web site may be having browser compatibility issues. Whenever I look at your web site in Safari, it looks fine however, when opening in IE, it’s got some overlapping issues. I just wanted to provide you with a quick heads up! Other than that, great site!

https://www.noobaa.com/

January 5, 2025

Right here is the right blog for anybody who wants to understand this topic. You realize so much its almost hard to argue with you (not that I personally would want to…HaHa). You certainly put a brand new spin on a topic that’s been written about for many years. Great stuff, just excellent.

https://accountlearning.com/

January 5, 2025

Spot on with this write-up, I absolutely feel this web site needs a lot more attention. I’ll probably be returning to see more, thanks for the advice.

http://accountlearning.com/

January 5, 2025

The next time I read a weblog, I really hope who’s doesnt disappoint me approximately this one. I mean, I know it was my choice to read, but When i thought youd have something intriguing to convey. All I hear is really a few whining about something that you could fix if you werent too busy searching for attention.

https://ucgp.jujuy.edu.ar/profile/malecarbon2/

January 5, 2025

I need to test with you here. Which is not one thing I usually do! I get pleasure from reading a post that will make folks think. Also, thanks for allowing me to comment!

https://stack.amcsplatform.com/user/plotbeat4

January 6, 2025

An outstanding share! I’ve just forwarded this onto a colleague who had been conducting a little research on this. And he in fact ordered me breakfast because I found it for him… lol. So allow me to reword this…. Thank YOU for the meal!! But yeah, thanks for spending time to talk about this issue here on your website.

https://childcentre.info/

January 6, 2025

Good blog you have here.. It’s hard to find quality writing like yours these days. I honestly appreciate individuals like you! Take care!!

http://childcentre.info/

January 6, 2025

Aw, i thought this was quite a nice post. In notion I would like to put in place writing such as this additionally – taking time and actual effort to generate a very good article… but so what can I say… I procrastinate alot and also no means manage to go completed.

https://escatter11.fullerton.edu/nfs/show_user.php?userid=7713730

January 6, 2025

both David Cook and David Archuleta are the best in my opinion, they have this unique voice.

https://www.youtube.com/redirect?q=https://andypaintingservice.co.uk/service-areas/maidstone/

January 6, 2025

The globally competitive BPO corporations within the nation supply providers not just in the voice sub-sector but also in non-voice, high worth companies akin to software growth, web design, desktop publishing, legal services, typesetting, composition, shared providers, graphic design, and animation.

https://bandori.party/user/244597/ijhxael/

January 6, 2025

Way cool! Some extremely valid points! I appreciate you penning this article and the rest of the website is also very good.

https://gonm.biz/

January 6, 2025

I used to be shocked to find out I was spending eleven hours per week on e-mail and 5 on Facebook (ugh).

https://rant.li/vpfoyrob/a-href-www-metooo-it-u-6772da5eacd17a11773df0cdlink-a-a

January 6, 2025

Hi, I do think this is an excellent blog. I stumbledupon it 😉 I’m going to return once again since I book-marked it. Money and freedom is the greatest way to change, may you be rich and continue to guide other people.

http://petheven.com/

January 6, 2025

Scottie pippen needs to slap himself for saying Lebron is better than Jordan smh no comparison james need more experience PERIOD !,RatherUniqueJ,

http://doodleordie.com/profile/gasengineers357

January 6, 2025

Thank you for some other informative website. Where else could I get that type of information written in such an ideal means? I’ve a venture that I am just now running on, and I have been at the look out for such information.

http://www.effecthub.com/people/gasengineers464

January 6, 2025

Pretty! This was an extremely wonderful post. Many thanks for providing this info.

https://www.noobaa.com/

January 6, 2025

Minimize yarn alongside opposite edge of cardboard.

https://www.showmethesite.us/lazychicken/ActivityFeed/MyProfile/tabid/2622/UserId/703574/Default.aspx

January 6, 2025

Glass block was originally developed within the early 1900s to provide pure mild in industrial factories.

https://fab-chat.com/members/EkTuLYF/profile/

January 7, 2025

The Driver and Vehicle Requirements Company declares that every one pending sensible and driving principle exams are to be postponed, for at the least three months in the case of sensible exams, and up to and together with 20 April for concept tests.

https://telegra.ph/0103-ewpjhyexbfxgvdbkfkio-01-03

January 7, 2025

Excellent post. I’m experiencing a few of these issues as well..

https://childcentre.info/

January 7, 2025

power tools can really save you from a lot of headache, specially when the job is very hard,

https://shorl.com/nagramidibiny

January 7, 2025

??? ??? ???? ?????? ?? ????? ????? ????? ?? ?????? ?????? ????? . ????? ??????? ????? ?????? ????? ??????? ?????? ??????? ???? ????? ?????? ??????? ??? ?????? ??? ?? ??????? money ????? ????????.

https://www.akaqa.com/account/profile/19191701218

January 7, 2025

I couldn’t refrain from commenting. Well written.

https://childcentre.info/

January 7, 2025

I discovered your site web site on bing and appearance a few of your early posts. Maintain inside the very good operate. I recently additional up your RSS feed to my MSN News Reader. Looking for forward to reading much more from you at a later date!…

http://www.neighborhoodlink.com/people/gasengineers309

January 7, 2025

This site was… how do you say it? Relevant!! Finally I’ve found something which helped me. Thanks a lot.

https://gonm.biz/

January 7, 2025

Since the municipal reform of 1972, the borough of Hitzacker has consisted of the city itself and the eleven villages listed beneath.

https://www.showmethesite.us/lazychicken/ActivityFeed/MyProfile/tabid/2622/UserId/705603/Default.aspx

January 7, 2025

You ought to take part in a contest for one of the best sites on the internet. I’m going to recommend this blog!

https://www.hexenmod.com/

January 7, 2025

The only one at present in commercial production is the Darrieus turbine, which appears to be like sort of like an egg beater.

https://tvchrist.ning.com/profile/SPzDgkPS

January 7, 2025

I seriously love your site.. Pleasant colors & theme. Did you develop this website yourself? Please reply back as I’m looking to create my own blog and would like to find out where you got this from or what the theme is named. Appreciate it.

http://mhpa.ge/

January 8, 2025

I seriously love your site.. Great colors & theme. Did you build this web site yourself? Please reply back as I’m planning to create my very own site and want to learn where you got this from or just what the theme is called. Appreciate it!

https://dalebeckman.com/

January 8, 2025

I was able to find good info from your articles.

http://mhpa.ge/

January 8, 2025

However, before going all out with any specific remedy, test it out on an inconspicuous a part of the shoe to make sure it does not additional the damage.

https://rant.li/gjp/a-href-search-earth911-com-article-irecycle

January 8, 2025

Greetings! Very useful advice within this post! It is the little changes that make the most important changes. Thanks a lot for sharing!

https://izonemedia360.com

January 9, 2025

You’re so awesome! I don’t think I’ve read through anything like this before. So good to find somebody with some genuine thoughts on this subject. Really.. thank you for starting this up. This web site is something that’s needed on the web, someone with some originality.

https://www.dcsaasports.org/

January 9, 2025

Nonetheless, make-up consultants are divided in their views on one of the best ways to use that product.

https://www.sutori.com/en/story/untitled–CP9Hr9UMS9LBpXC2RjpxxXpR

January 9, 2025

No matter how you like to arrange your life-whether or not it’s with The Pleased Planner, a finance binder, a bullet journal, a digital planner, or a easy 1-inch binder-this free debt payoff planner is perfect for any planning system.

https://www.laundrynation.com/community/profile/uvw/

January 9, 2025

Nothing may be worse than paying harsh penalties after the non-fee of any tax.

https://postheaven.net/bewvt06f53

January 9, 2025

You have made some decent points there. I checked on the web for additional information about the issue and found most people will go along with your views on this site.

http://emojicheap.com/

January 9, 2025

This is a topic which is near to my heart… Best wishes! Where are your contact details though?

http://www.dcsaasports.org/

January 9, 2025

Nice post. I learn something totally new and challenging on blogs I stumbleupon on a daily basis. It will always be exciting to read content from other writers and use a little something from other web sites.

https://www.hexenmod.com/

January 10, 2025

Hi there! This post could not be written any better! Going through this post reminds me of my previous roommate! He constantly kept talking about this. I’ll forward this information to him. Fairly certain he will have a good read. Thank you for sharing!

https://gonm.biz/

January 10, 2025

Start your day looking fresh and awake by shaping your eyes with an eyeliner from our extensive collection. Choose a neutral eyeliner shade, such as brown or tan, to give you a more natural look that’s ideal for daytime activities. Yves Saint Laurent, M·A·C and Lancôme all offer thin-tipped eyeliner pencils that let you add a slight line around your eyes so they stand out. intense eye pencil To further brighten the face, you can also invest in a chunkier white pencil (like the NYX Jumbo Eye Pencil), and apply it to the inner corner of the eye. This brings focus and light to the center of the face. Blend out with your finger for a diffused finish. Depending on the formula, eyeliners can have a life span that varies from three months to a year-plus, and anywhere in between. Look for anti-microbial properties in liquid liners to prevent bacteria from growing in the formula, and sharpen your pencils regularly to ensure a fresh layer of product is making contact with your eyes. If your eyeliner develops a weird film or changes in consistency, that’s a sign to replace it with a new one.

https://begindirectory.com/listings12889164/revolution-super-dewy-tinted-moisturiser

Filling in my brows takes around 15 minutes of my everyday prepping time. Sometimes, when my hand doesn’t cooperate, the time doubles up , because I had to erase everything and start over. After microblading, I already saved 15 minutes! Ideal for extremely sparse eyebrows We are passionate about elevating the art and industry of PMU and microblading. With Tina Davies products, success is at your fingertips! Book Eyebrow Embroidery Specialist Directly to You Eyebrowsmicroblading1 Microblading proseduru Because color is impacted closer to the surface, the hair strokes appear very crispy and fine. This method is ideal for anyone wanting to enhance the look of his or her eyebrows but not suitable for oily, problematic skin. Pros: The combination of microbladed hair strokes and a powder fill gives an incredibly natural looking brow. It’s a bit more defined and filled in than just straight microbladed brows, and a bit less solid and dramatic than the ombre powder fill.

January 10, 2025

What are your zoning requirements?

http://www.if-hgtib.xyz/blog/how-to-make-marshmallow-flowers-a-creative-craft-with-sweet-inspiration

January 10, 2025

Great web site you’ve got here.. It’s difficult to find high-quality writing like yours these days. I honestly appreciate people like you! Take care!!

https://social-rise.com/schedule-reddit-posts

January 10, 2025

But if there are riders, weigh the pros and cons of these attachments to make sure the headache of owning the historic property is worth the benefits.

http://www.ale-since.xyz/blog/who-has-hot-honey-pizza-an-insightful-discussion

January 10, 2025

Have you ever executed my venue earlier than?

https://designaddict.com/community/profile/EdHiGFn

January 10, 2025

The capture by force of docked ships led to fighting between Free French sailors and outnumbering British Marines, sailors, and soldiers within the English harbours.

https://kaeuchi.jp/forums/users/rxuwtacr/

January 11, 2025

May I simply say what a relief to discover someone that truly understands what they are talking about over the internet. You actually know how to bring a problem to light and make it important. More and more people need to look at this and understand this side of your story. I was surprised you’re not more popular given that you definitely possess the gift.

https://ecrypto1.com/

January 11, 2025

Hi there! I just would like to offer you a big thumbs up for your excellent info you’ve got right here on this post. I am returning to your web site for more soon.

https://www.hexenmod.com/

January 11, 2025

Can I simply say what a relief to find an individual who actually understands what they are discussing online. You certainly understand how to bring a problem to light and make it important. A lot more people should look at this and understand this side of the story. I can’t believe you aren’t more popular because you most certainly have the gift.

https://supplementfind.com/

January 11, 2025

They moved to sixty one Deodar Highway in Putney which that they had transformed to house a studio and workshop, which was shared by fellow stained glass artist M. E. Aldrich Rope.

http://www.wvddv-still.xyz/blog/1736324752491

January 12, 2025

You made some good points there. I looked on the web for more information about the issue and found most people will go along with your views on this web site.

https://knoxentzz.blogkoo.com/the-best-side-of-proxy-51646904

January 13, 2025

Remarks: This match resulted in a rook ending the place Black was down a pawn, but each sides have been successfully stalemated as neither were capable of advance their pawns.

http://www.kxuwey-could.xyz/blog/1736268736430

January 13, 2025

Monday to Friday earlier than 7 am and after 10 pm.

https://www.divephotoguide.com/user/usqbogwefsimdqcbhb

January 13, 2025

This data consists of placement within the race, lap quantity, car quantity and the period of time every driver lags behind the chief.

https://telegra.ph/0107-jwsxtwueddcjezgc-01-07

January 13, 2025

Howdy! This article could not be written much better! Looking at this post reminds me of my previous roommate! He always kept preaching about this. I most certainly will send this article to him. Pretty sure he will have a very good read. Thank you for sharing!

https://www.series-hot.net/

January 14, 2025

This is a topic which is near to my heart… Thank you! Where are your contact details though?

https://xxxsnatch.com

January 15, 2025

Latest in crypto technology

January 15, 2025

прием к гинекологу

January 16, 2025

осмотр у гинеколога при беременности

January 16, 2025

осмотр врача гинеколога

January 17, 2025

Reed cautions Victor that the calculations for the machine are incorrect, however Victor dismisses the warning.

http://www.kdlrt-court.xyz/blog/1736689048551

January 17, 2025

Looking forward to your next post. Keep up the good work!

January 17, 2025

Универсальная зарядная станция – это решение для владельцев различных гаджетов, позволяющее заряжать все устройства одним аксессуаром.

January 17, 2025

консультация гинеколога в днепропетровске

January 17, 2025

консультация гинеколога в днепропетровске

January 17, 2025

осмотр у гинеколога после родов

January 17, 2025

That is a really good tip particularly to those fresh to the blogosphere. Simple but very accurate information… Thanks for sharing this one. A must read post!

https://q5id.com/

January 17, 2025

Batteries can retailer a certain amount of the photo voltaic power in order that the zeroHouse has sufficient energy to run even without the brilliant sun.

https://rant.li/dviktocwv/a-href-forum-issabel-org-u-handleenemy9link-a-a

January 17, 2025

прием у гинеколога

January 17, 2025

This is a topic which is close to my heart… Thank you! Exactly where can I find the contact details for questions?

https://www.lesnapoleons.com/

January 18, 2025

Your blog has quickly become one of my favorites I always look forward to your new posts and the insights they offer

January 18, 2025

Excellent blog post. I absolutely appreciate this site. Keep it up!

https://engage.bz/

January 18, 2025

This blog has opened my eyes to new ideas and perspectives that I may not have considered before Thank you for broadening my horizons

January 18, 2025

I quite like reading an article that can make men and women think. Also, many thanks for allowing me to comment.

http://warriorangelsfoundation.org/

January 18, 2025

гинеколог врач

January 18, 2025

записаться на прием к гинекологу

January 18, 2025

прием у гинеколога

January 18, 2025

Your posts always seem to lift my spirits and remind me of all the good in the world Thank you for being a beacon of positivity

January 18, 2025

хороший гинеколог

January 18, 2025

частный гинеколог

January 18, 2025

обследование гинеколога

January 18, 2025

A motivating discussion is worth comment. I believe that you ought to publish more about this subject, it may not be a taboo matter but generally people do not discuss these issues. To the next! Many thanks.

https://fairleevt.org/

January 18, 2025

лучший гинеколог

January 18, 2025

This website was… how do you say it? Relevant!! Finally I have found something that helped me. Cheers!

https://mhpa.ge/

January 18, 2025

Blockchain Consulting companies specializing in blockchain implementation can help you take advantage of tried-and-true design methodologies and capabilities, resulting in faster time to value for your business.

https://cadillacsociety.com/users/AlV

January 18, 2025

Time is cash as the saying goes, and if it can save you time your can usually promote your product.

https://designaddict.com/community/profile/HbwGWM

January 18, 2025

врач гинеколог

January 18, 2025

гинеколог прием

January 19, 2025

Your Money or Your Life: Revised and Updated for the 21st Century, published by Penguin Books in December 2008 by Vicki Robin with Monique Tilford and contributor Mark Zaifman.

http://www.wdzejw-all.xyz/blog/1736923012881

January 19, 2025

This post hits close to home for me and I am grateful for your insight and understanding on this topic Keep doing what you do

January 19, 2025

Your blog is like a breath of fresh air in a sea of negativity and pessimism Thank you for being a source of light and hope

January 19, 2025

Fortuitously, there may be one in Poland that matches the description perfectly – Warsaw, Cracow or maybe Tricity?

https://tvchrist.ning.com/profile/BOnhuPYh

January 19, 2025

Within the case of facultative symbiosis, the symbiotic relationship gives each organism a higher probability of survival but is not absolutely mandatory.

https://www.outdoorproject.com/users/naen-blqonif

January 19, 2025

This website was… how do you say it? Relevant!! Finally I have found something that helped me. Thanks.

https://dimple1107.com/

January 19, 2025

We deeply cherish your support, which inspires our journey toward better achievements. Thank you!

https://vanillagift.xyz/

January 19, 2025

I know you said you possibly can begin the place you’re at, but are there any abilities that canines and handlers do need before signing up?

https://rant.li/hyn/a-href-shuidi-cn-openwebsite

January 19, 2025

Native sources will have the ability to give you help that can assist your workplace run easily, as they know the lay of the land and are in a better place to offer assistance with occasion planning and emergency preparedness.

https://forum.reallusion.com/Users/3224021/nikolajtimofeevln6210

January 19, 2025

In the years after the WTC’s completion, skydivers successfully parachuted from the top of the towers, climbers scaled the building and a French acrobat walked back and forth between the buildings on a tightrope.

http://www.particular-cuppua.xyz/blog/1737285708592

January 19, 2025

The UPS Worldport, viewed from above At most airports, individuals use brightly-coloured cones or flares to manually direct the pilots as they land and taxi.

https://rant.li/bqhicbxe/a-href-www-google-fr-url

January 19, 2025

FRM certification, offered by The Global Association of Risk Professionals (GARP) is awarded after a candidate has passed two rigorous exams and demonstrated two years of relevant work experience.

http://www.vajjd-green.xyz/blog/1737285715753

January 19, 2025

Om Dutt Sharma, who has created a faculty, clinic and free dispensary for the youngsters of his village, shouldn’t be a Silicon Valley millionaire; he will not be a rich physician nor a businessman who makes hundreds of thousands.

http://www.where-bmicp.xyz/blog/1737285700670

January 19, 2025

Giovanni is working with combative authorized firm Schillings and is predicted to put ahead transcripts to prove he acted pretty.

https://6bupec9w8f.blogspot.com/2025/01/j9mH3HvK.html

January 19, 2025

Initially on the books at Cambridge United as a boy, he joined West Ham United in 2005 and was with the Hammers for eleven years, and through that time he received caps for the Republic of Eire at beneath-17, under-19 and beneath-21 degree.

http://www.ljwdk-add.xyz/blog/1736268701845

January 19, 2025

mlzuu9

January 20, 2025

113 A. Wayman and H. Wayman, trs., The Lion’s Roar of Queen Srimala: A Buddhist Scripture on the Tathagatagarbha Idea (New York: Columbia U.P., 1974); see the introduction.

https://www.outdoorproject.com/users/hcexjho-aqwky

January 20, 2025

The MetaMask Wallet is essential for managing your crypto securely. I used https://metalead.org/ to download it, and the instructions for the MetaMask Chrome extension were clear and concise.

January 20, 2025

Read about this nice yard game on the subsequent web page.

https://designaddict.com/community/profile/vRAZYY

January 20, 2025

Thank you for always being open and honest with your readers It’s refreshing to see a blogger who is unafraid to be vulnerable and real

January 20, 2025

Thank you for always being open and honest with your readers It’s refreshing to see a blogger who is unafraid to be vulnerable and real

January 20, 2025

I completely agree with your perspective on this topic It’s refreshing to see someone presenting a balanced and thoughtful viewpoint

January 20, 2025

Greetings! Very helpful advice in this particular post! It is the little changes that produce the biggest changes. Thanks for sharing!

https://q5id.com/

January 20, 2025

Gap analysis provides a foundation for measuring investment of time, money and human resources required to achieve a particular outcome (e.g.

http://www.jiq-offer.xyz/blog/if-my-rent-increases-will-my-food-stamps-increase

January 20, 2025

As a matter of fact, those who have the ability to invest wisely in real estates, tend to lead life of comfort.

http://www.xbwf-could.xyz/blog/1737361335754

January 20, 2025

Right here is the perfect webpage for anyone who hopes to understand this topic. You realize so much its almost tough to argue with you (not that I actually would want to…HaHa). You definitely put a new spin on a topic that has been discussed for many years. Great stuff, just wonderful.

https://www.lesnapoleons.com/

January 20, 2025

Your blog has become my go-to source for inspiration and motivation I am so grateful for the valuable content you provide

January 20, 2025

At the same time as the tram community, Freiburg had entry to electric highway lighting that was powered by the identical electricity plant, which still exists right this moment, and is situated on Eschholzstraße, away from the tram community.

https://zenwriting.net/96tnip8odd

January 20, 2025

Fortunately, continuing improvements over the previous decade-plus have made affordable, extremely environment friendly photo voltaic energy extra readily available to extra individuals all through the world.

http://www.today-gzga.xyz/blog/1737360758466

January 21, 2025

So she granted the charter for the East India Company.

http://www.qfqldp-despite.xyz/blog/1737042583231

January 21, 2025

Irwin, Neil (30 July 2013).

https://designaddict.com/community/profile/wUYLgd

January 21, 2025

Excellent article. I absolutely love this site. Stick with it!

http://fairleevt.org/

January 21, 2025

These are some basics on that compose it.

https://cadillacsociety.com/users/rCLP

January 21, 2025

You can also speculate on the price of spread betting, trading CFDs and other financial derivatives markets.

https://postheaven.net/d1j5o2ep3l

January 21, 2025

This is a topic which is close to my heart… Many thanks! Where can I find the contact details for questions?

https://nolose.org/

January 21, 2025

Operation Torch rallied the Army of Africa to the Free French cause and likewise infuriated Hitler, who ordered the occupation of the remainder of metropolitan France (the “free zone”), as well as air raids against French Algerian cities by the Libya-based Luftwaffe.

https://cadillacsociety.com/users/yFPpgS

January 21, 2025

If you flip your automotive in for a new lease, you may need to pay an additional $1,800 on prime of any fees you have to pay to start the next lease.

https://postheaven.net/10fyytpatb

January 21, 2025

Her ability to push the envelope with out going overboard and her quirky character have made her a favourite style blogger for a lot of.

https://designaddict.com/community/profile/hQCgKyL

January 21, 2025

As a fellow blogger, I can appreciate the time and effort that goes into creating well-crafted posts You are doing an amazing job

January 21, 2025

The reference card is offered as a PostScript file which, when printed on a PostScript printer, produces a one-page reference card that lists greater than 230 French “glue words” along with their English translations.